Offset printing labels – is it worth the effort to set up and the overall cost? After all, the method you choose is less of a significant impact on quality thanks to the improvements in label print tech. The intended application and required turnaround times are the focus areas in 2024 & beyond.

For decades, offset printing has been the go-to for producing labels on rolls, particularly for high-volume print runs. This technique, known for its exceptional print quality and suitability for large quantities, has been serviceable for businesses needing consistent, high-quality labels.

However, as market demands shift towards more flexible, timely, and cost-effective solutions – digital printing is emerging as a formidable contender.

Why Offset Label Printing Has Been Preferred – Until Now

Offset printing’s appeal for label production, especially on rolls, stems from several key advantages:

- Suitability for High Volumes: Offset printing is incredibly efficient for large-scale label or sticker runs, making it cost-effective for long-term projects requiring thousands, if not millions, of the same label design and shape.

- High Setup Costs but Economical for Bulk: While the initial setup fees for offset label printing can be substantial due to the need for creating plates and configuring the press, these costs are amortised over large print runs, reducing the per-unit cost significantly.

- Quality and Precision: Known for its high-quality outputs, offset printing can produce stickers with crisp, clear images and vibrant colours. The technique is also conducive to die-cutting, allowing for precise shapes and sizes.

- Consistency: For brands that require consistency across batches produced over time, offset printing offers great uniformity, ensuring that each label looks exactly like the last, even over extended periods.

Despite these advantages, offset printing’s inflexibility with ‘kinds’ (variations in design or content within the same print run) and its high setup costs have prompted businesses to seek more adaptable printing solutions.

Shifting Trends: The Move Towards Digital Printing

The landscape of label printing is changing, driven by evolving business needs and technological advancements. The trend towards ‘just-in-time’ purchasing and the decreasing desire to hold large inventories are significant factors influencing this shift. Here’s why digital printing is becoming the preferred choice for labels and stickers:

- Agility and Flexibility: Unlike offset printing, digital printing does not require plates, significantly reducing setup times and allowing for greater flexibility in print runs. This agility is crucial for businesses looking to respond quickly to market demands or make last-minute changes to their labels.

- Economical for Shorter Runs: Digital printing is more cost-effective for smaller quantities, making it an ideal choice for businesses that require high-quality labels but in lower volumes. This aligns perfectly with the trend towards smaller, more frequent print runs as companies adopt a ‘just-in-time’ inventory approach.

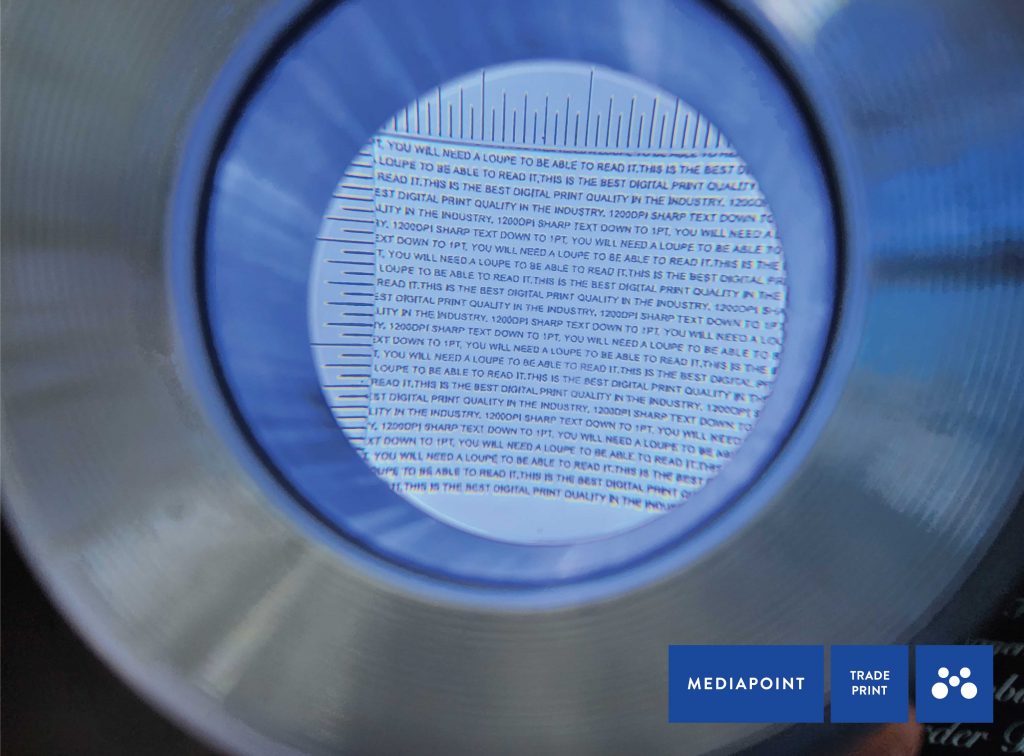

- Quality that Matches or Surpasses Offset: Advances in digital printing technology mean that it can now match or even surpass the quality of offset printing labels. High-resolution digital printers can produce labels with incredible detail, vibrant colours, and even achieve fidelity and micro sizes that offset printing struggles with.

- No Constraints on ‘Kinds’: Digital printing offers the ability to print multiple designs in the same run without incurring additional costs. This flexibility is a boon for businesses that require a variety of label designs or frequently update their label content.

Embrace the Offset Label Printing Alternatives

The flexibility, cost-effectiveness for shorter runs, and high-quality outputs, makes digital printing a compelling alternative to offset label printing. It also matches the shifting dynamics of consumer demand and inventory management that tilt in favour of agile production.

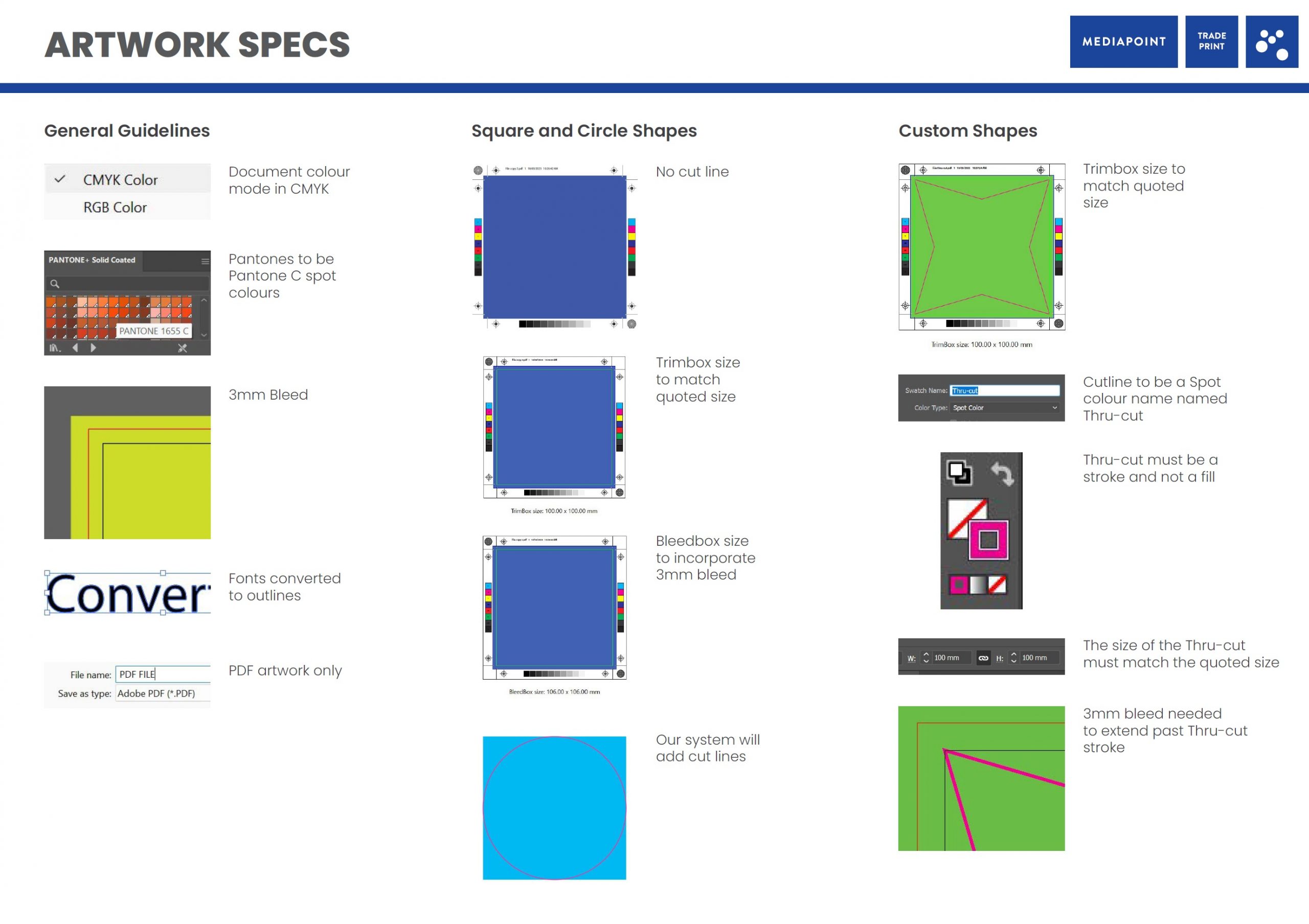

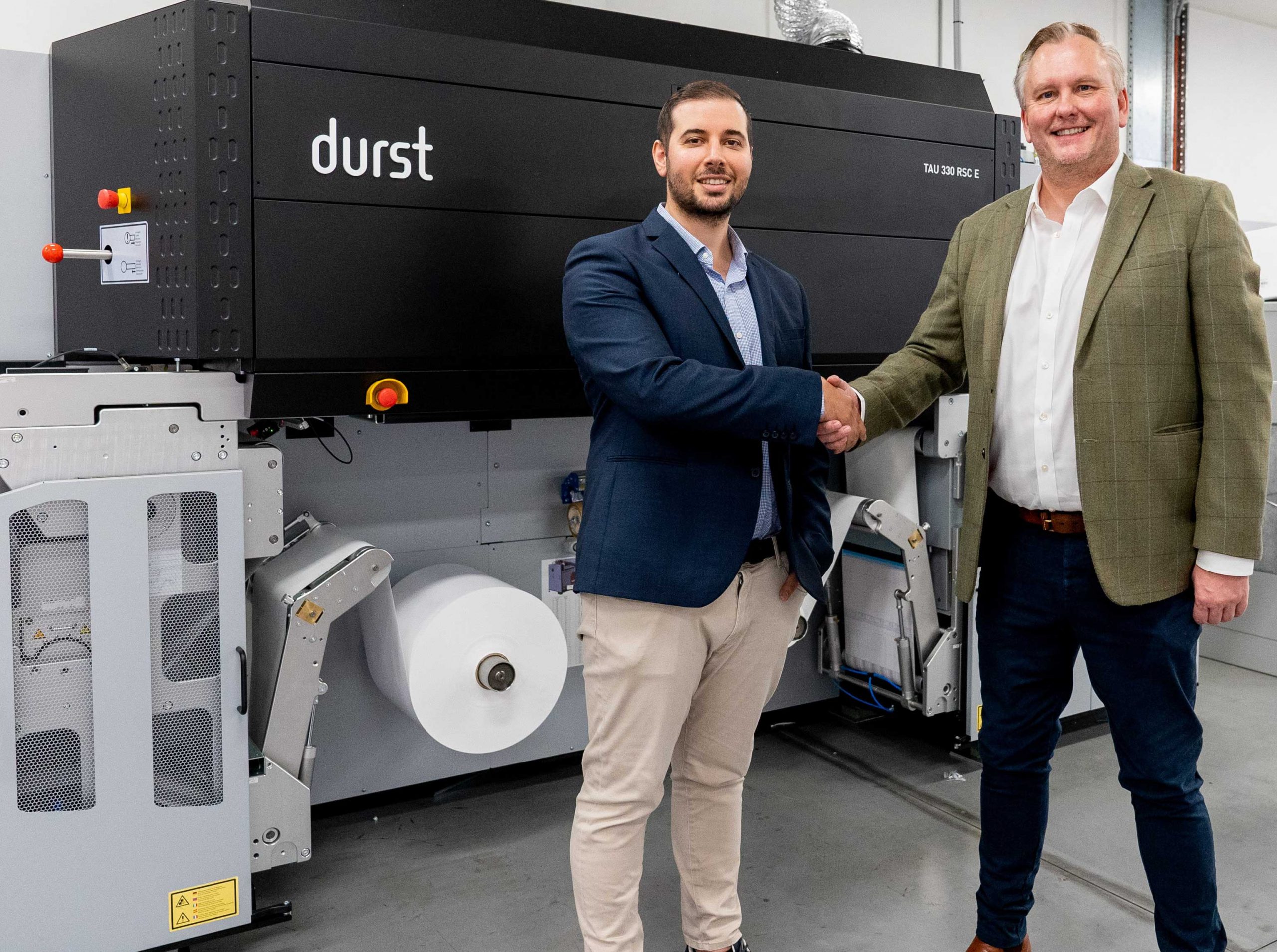

At Mediapoint, we embrace the latest in digital printing technology, offering our clients unmatched quality, a wider range of sticker / label products, and better margins for reselling.

As the industry continues to evolve, so too will the technologies we use, ensuring that your labels always make the best impression, no matter how big or small the job.

Not yet a part of our trade print community? Sign up for a trade account in minutes – Click Here.