In the realm of commercial printing, offset printing has long been the go-to process. Offset print is often sought for its ability to churn out large volumes at breakneck speeds. This traditional method, wherein designs are transferred from plates to rollers and finally onto the media, has dominated the industry for years. We’re pretty sure that when you think of large format print, you’ve probably got the image of an offset printer in your head! That’s despite the fact that it’s increasingly becoming the less-preferred process for production.

The tide is turning, and at Mediapoint, we’re riding the wave of change. It’s a decision driven by unparalleled advancements in technology and the evolving needs of clients. For most use cases, digital printing has reached parity with offset processes.

So let’s dive into the how and why…

Understanding Offset Printing

Offset printing’s legacy in the mass production of prints is undeniable. It’s been the go-to for businesses needing large print runs due to its efficiency and consistency.

The Benefits:

- High-Quality Images and Textures: Offset printing produces rich, accurate colors and high-quality images with finer detail and without streaks or spots. The method’s ability to use a wide range of printing substrates also means textures and finishes can be more diverse.

- Cost-Effectiveness for High Volumes: For large print runs, offset printing becomes incredibly cost-effective. The initial setup costs are offset by the lower per-unit cost at higher volumes, making it ideal for printing large quantities.

- Colour Consistency: The process allows for excellent colour matching and consistency across a print run, which is vital for branding and high-quality art reproductions.

The Drawbacks

Naturally, there are drawbacks to traditional printing processes – particularly as equipment manufacturers continue to innovate in the spaces.

- High Initial Setup Costs: The need to create plates for each print job incurs significant initial costs, making offset printing less economical for small to medium-sized print runs. This setup process also requires time and planning, which can be a disadvantage for projects with tight deadlines.

- Inflexibility in Print Runs: Once an offset print run has begun, making changes can be costly and complicated. This inflexibility means errors or last-minute updates can result in increased costs and wasted materials.

- Size Limitations: The physical dimensions of the offset press limit the size of the print job. This can restrict the potential for larger formats that are increasingly popular in advertising and display materials.

- Environmental Concerns: The process involves more waste than digital printing, from the plates that often cannot be reused to the excess ink and water usage. Additionally, the pigment-based inks used in offset printing typically have volatile organic compounds (VOCs) that can be harmful to the environment.

- Durability Issues with Pigment-Based Inks: While offering vibrant colors, the pigment-based inks used in offset printing are less durable when exposed to UV light and the elements, leading to quicker fading and degradation of outdoor materials.

These factors led us at Mediapoint to explore and ultimately embrace the possibilities offered by digital printing technologies. We’ve been investing heavily in keeping at the edge of these technologies – and we’re not quiet about it either. You may have even seen us featured in ProPack, manufacturer case studies and other printing media.

So let’s dive into why we’re all in on digital…

Why Mediapoint Chooses Digital Over Offset Printing

Superior Print Quality

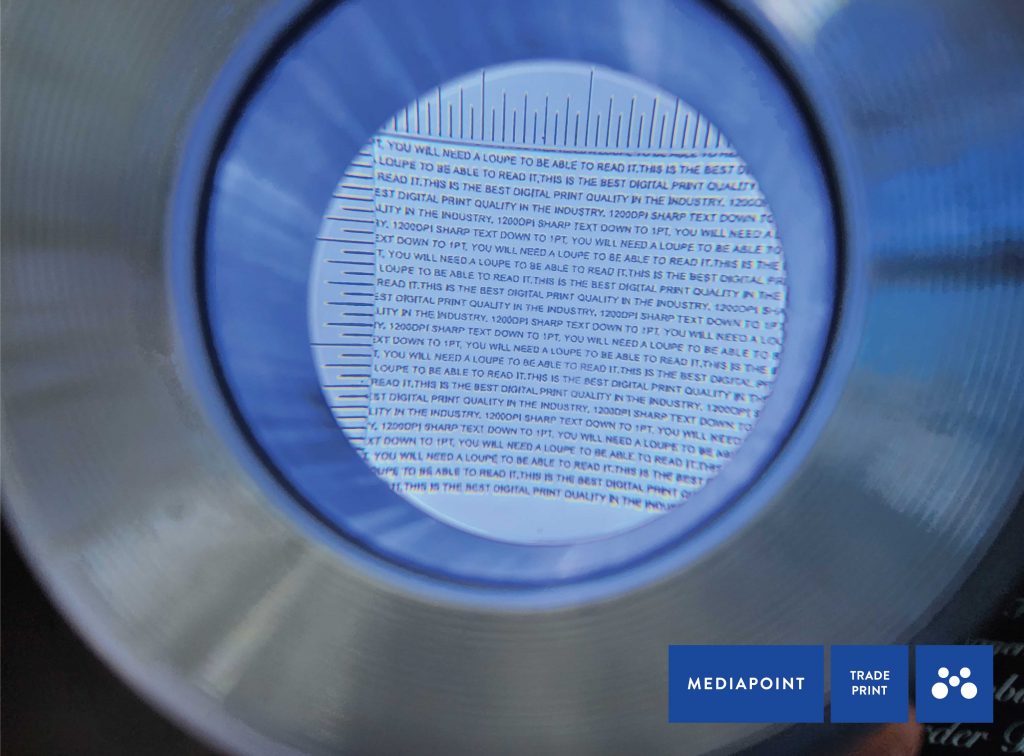

One of the most compelling reasons for our shift towards digital printing is the remarkable quality it can achieve. Our Durst Tau UV roll printer stands as a testament to this, capable of printing intricately detailed 1pt text and 5mm QR codes that are crystal clear under a loupe. As you can see below you can get very creative with roll labels and stickers – unlocking applications galore.

This level of precision was once thought to be the exclusive domain of offset printing, but digital technology has not only caught up; it’s starting to surpass.

Flexibility and Customisation

Digital printing eliminates the need for plates, a staple in the offset printing process. This removal not only reduces setup times but also opens up a world of customisation and flexibility for our clients.

At Mediapoint, we’ve leveraged this to eliminate kind fees on a wide array of products, making it more economical for our clients to print exactly what they need, regardless of the batch size.

Size and Material Versatility

Another advantage digital printing holds over offset is its adaptability in terms of print sizes and materials. Offset printing’s size limitations often restrict creative ambitions, especially for large format needs.

Digital printing, on the other hand, accommodates a broader range of sizes and substrates, ensuring that our clients’ visions aren’t constrained by technical limitations. We can print simple and complex designs, with high-fidelity on more materials than traditional offset printing would allow. And you’ll never be upset by more choice as a printing reseller, right? An increase in options and better outcomes for your own customers is always a positive.

Durability and Longevity

When it comes to outdoor applications, the UV durability of prints is paramount. Offset printing’s reliance on pigment-based inks falls short in this regard, especially compared to the UV inks used in digital printing.

These digital inks are not only more vibrant but also offer enhanced resistance to the elements, ensuring that prints remain fade-resistant and durable over time.

LOOKING FOR OFFSET PRINTING? WE’VE GOT YOU COVERED.

At Mediapoint, our commitment to providing top-tier printing solutions has led us to fully embrace digital printing. This technology aligns with our goals of offering high-quality, versatile, and cost-effective print options to our clients. By prioritising digital over offset, we’re not just keeping pace with technological advancements; we’re offering our clients the best the printing world has to offer.

Whether you’re looking to bring a creative vision to life, enhance your brand’s marketing materials, or simply explore the vast possibilities of digital printing, Mediapoint is here to make it happen. Contact us today to discover how our digital printing solutions can benefit your next project. Let’s create something remarkable together.