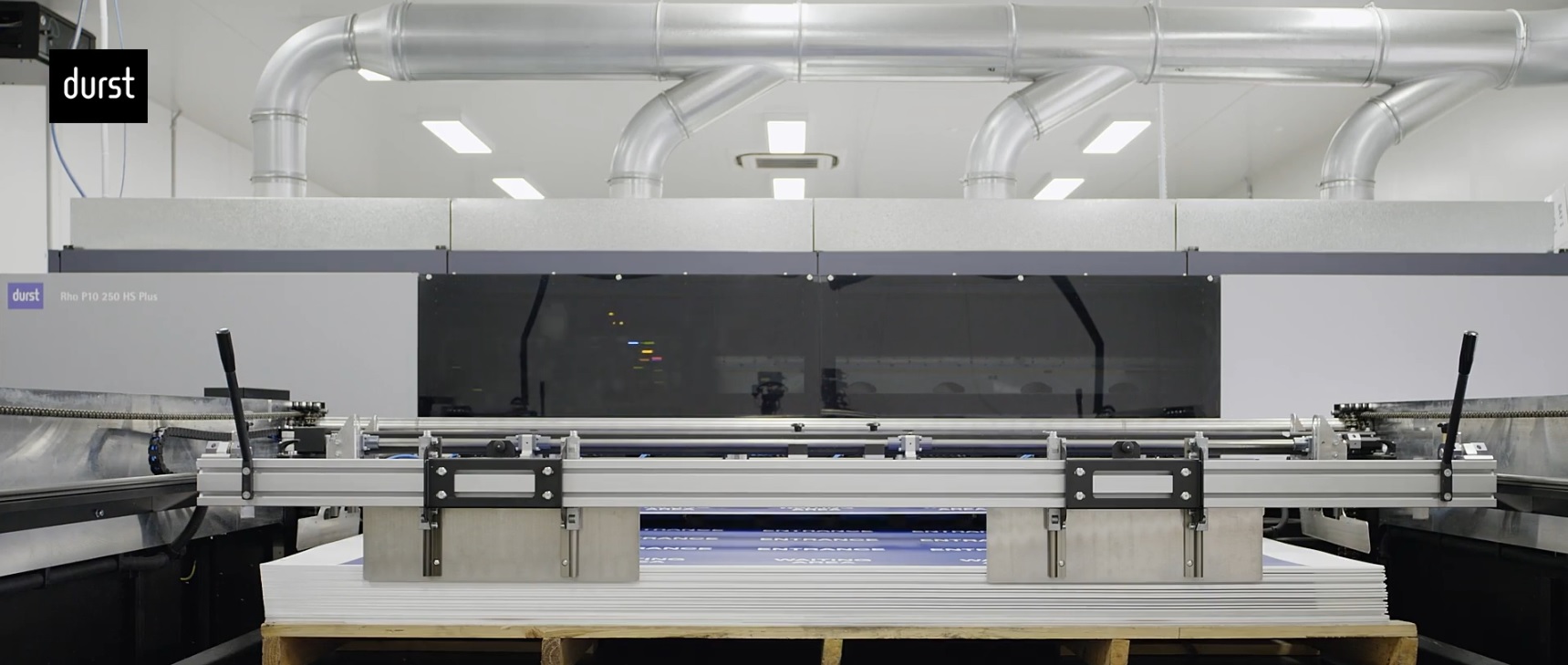

Jamie recently visited our major equipment supplier (Durst) in Europe and got the lowdown on the latest trends in print reselling. Watch the above video keep an eye out for more content to learn more ahead of 2023.

As a trade printer, we are committed to keeping our clients informed of market movements. During our visit with Durst (and nearby customer factories) we learnt of several noteworthy trends for our print partners.

Packaging (including Stickers and Labels) is a Fast-Growing Product Segment

One of the most significant trends was the growing demand for packaging, stickers, and labels. This is a product line that has seen significant growth in recent years. It is showing no signs of slowing down!

This is likely due to the fact that packaging, stickers, and labels are becoming increasingly crucial to businesses in order to stand out in the crowded, global marketplace. Branding is a key aspect of customer experience and perception for both eCommerce and traditional shopping experiences – packaging influences both these areas heavily.

Print resellers specialising in this product line can expect demand for new, innovative packaging products. There is a significant opportunity to expand offerings and increase revenue in 2023. It’s a good thing that we’re on the front foot at Mediapoint.

We have new, specialised equipment on the way. This will enable our wholesale print partners to capitalise on this growth and deliver high-volume, high-quality, packaging solutions.

Some Trends in Print Reselling Will Continue

Another trend we observed was the continued demand for outsourced, large format printing. Business overheads continue to skyrocket, capital for assets is hard to come by, and supply chains still remain somewhat fragile. So, we will continue to see businesses outsourcing large format printing rather than keeping things in-house.

Large format printing requires specialised equipment, expertise, and experience that many companies do not possess. A quick cost-benefit analysis leads many retail-customers (and traditional print shops themselves) to see that outsourcing is generally the most effective option.

Turnaround for Print Equipment Manufacture is Accelerating

In good news for us (and our clients) the manufacture of specialised print equipment is returning to pre-covid volume. Plus, turnaround time continues to decrease on new equipment. That enables our network to take advantage of growing product lines by having the right equipment in place ahead of peak demand. As mentioned above we have some new machines on order. These should be in place to extend our offerings by Q2 of 2023.

It’s also an encouraging sign for the industry as a whole. We can infer that the market for wide format, flatbed, and specialised printing solutions is getting back on track.

Positive Outlook for Print Reselling

Overall, our visit highlighted a return to normality for trade printers and print resellers globally. We forecast that trends in the print reselling that were interrupted by COVID-19 will continue unabated through the next couple of years. Print brokers who can move fast, establish good connections with trade printers, and identify new customers looking for growing product lines are in for solid growth through to 2025 and beyond.

If you’d like to learn more about our current packaging production capabilities, or be first in line for new stickers and label products, make sure you sign up for a PrintIQ account.