In this article, we take a deep dive into the real costs of large format printing, breaking down each factor to help you understand where efficiencies can be gained and why outsourcing to a trade printer like Mediapoint might be your best option.

By understanding these costs, you’ll be better equipped to make informed decisions about whether in-house production is feasible or if utilising a trade printer can offer better margins and operational efficiency.

Large Format Printing Equipment: Cost & Capacity

First, let’s talk about one of the biggest upfront costs—the equipment itself. Large format printers come with a significant capital expenditure, which needs to be factored into the cost of each print run.

Many businesses consider buying their own equipment to avoid outsourcing costs, but it’s important to remember that purchasing is just the beginning. You must also consider ongoing maintenance, repairs, and the lifespan of the machine.

At Mediapoint, we’ve invested in high-capacity large format printers designed to handle substantial volumes. The advantage of this investment is twofold: it lowers the cost per sheet and increases the number of jobs we can process per hour.

With streamlined batch processing and efficient operations, we can push more volume through in less time. This creates a cost-saving domino effect that benefits our trade clients by offering them greater margins when reselling.

For businesses handling high-volume orders, this efficiency is critical. However, smaller print shops might find it hard to justify the expense of purchasing and maintaining their own large format equipment when those same efficiencies are hard to achieve at a smaller scale.

How Ink Factors Into the Costs of Large Format Printing

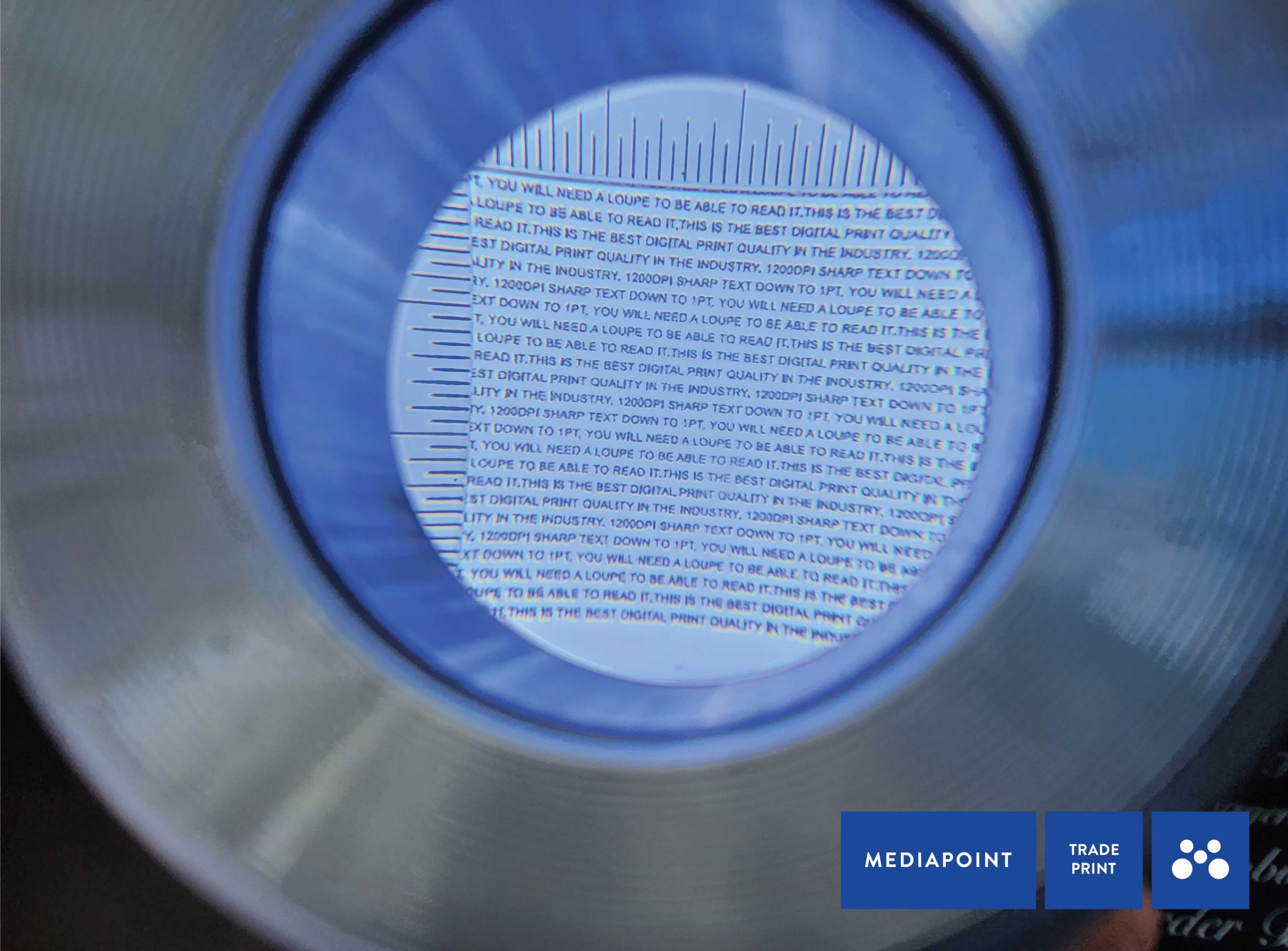

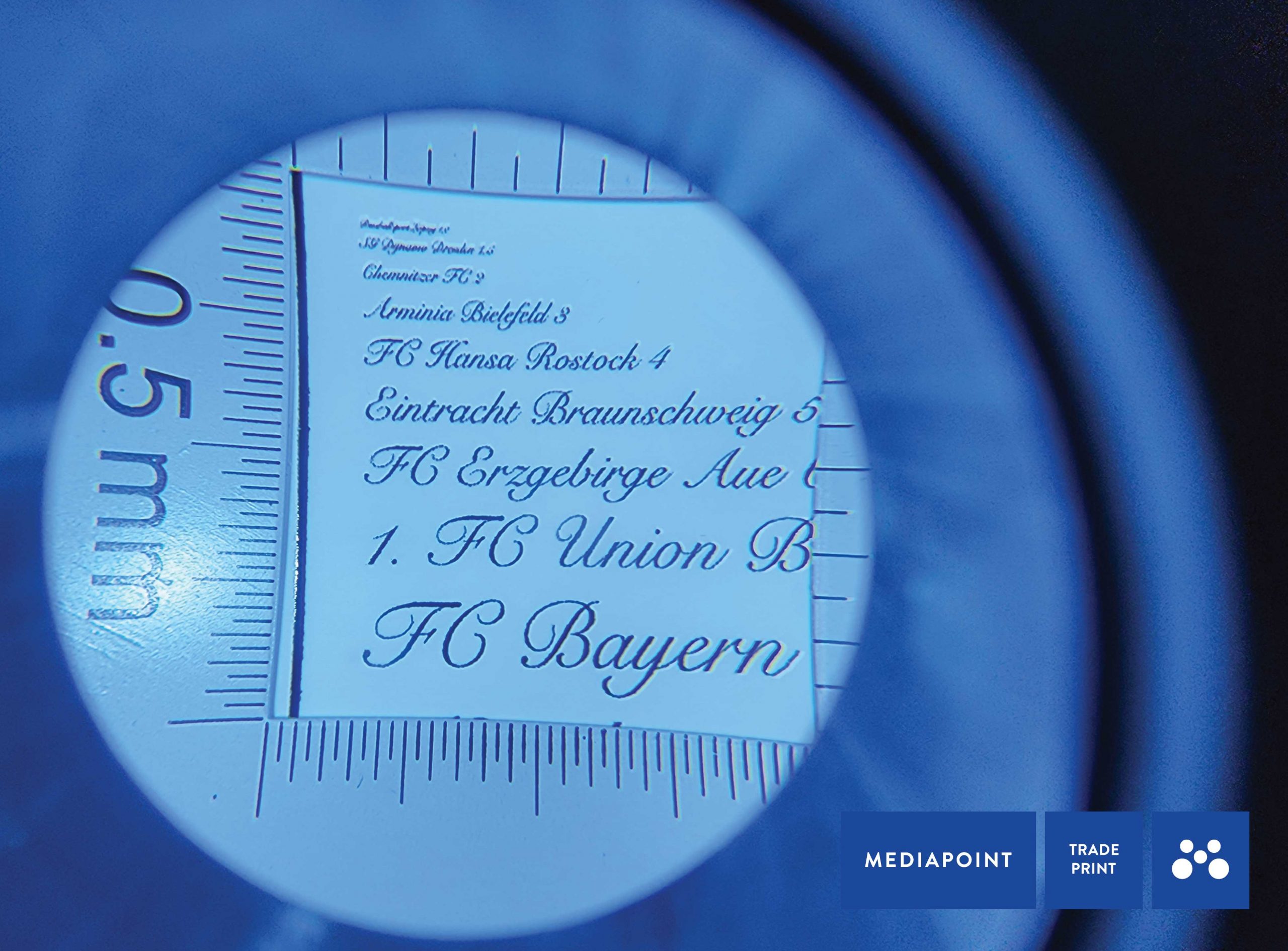

It’s no secret that ink is a major factor in print production costs, especially in wide format printing where ink usage can be significant. Ink is priced per square metre, and while you can technically achieve good results with entry-level equipment, the ink consumption on these machines is typically higher.

At Mediapoint, we’ve chosen to run premium Durst printers, specifically optimised to handle large volumes while maintaining efficient ink usage. By operating with a consistent print mode across all batches, we ensure that our ink consumption remains predictable and cost-effective, helping our trade clients keep their pricing competitive without sacrificing print quality.

For print businesses, the difference in ink efficiency between an entry-level printer and a high-end machine like those at Mediapoint can significantly impact profit margins. Inefficient ink usage, over time, leads to higher costs, which directly affects your pricing and competitiveness in the market.

Space Costs for Large Format Printing

Another often overlooked cost is the space required to house large format printers. These machines aren’t just big—they require substantial floor space for handling stock, production processes, and dispatch areas. If your business is considering scaling up, this means you’ll need to factor in the cost of additional real estate or storage.

At Mediapoint, we operate in over 2,000 square metres of internal warehouse space. This allows us to handle high volumes safely and efficiently, ensuring that production doesn’t slow down due to space limitations. Our large facility also means we are future-proofed, with the ability to take on more capacity as our business (and yours) grows.

Smaller print businesses that have maxed out their floor space may find themselves having to rent or purchase additional premises to house new equipment, which can drastically increase overheads. In contrast, by outsourcing to a trade printer with ample space and capacity, you can avoid this significant cost.

The Hidden Costs of Large Format Finishing

Finishing is another vital but frequently underestimated component of the total cost of wide format printing. Finishing equipment, such as cutting or laminating machines, often comes with a price tag as high—or even higher—than the printing equipment itself. Add in labour costs, training staff, and the time needed to complete these processes, and the expenses continue to climb.

At Mediapoint, we’ve invested heavily in top-tier finishing equipment and optimised our processes for maximum efficiency. This not only ensures a flawless final product but also allows us to pass on savings to our clients by keeping production times short and costs low.

For print businesses weighing the pros and cons of in-house production, finishing is a critical factor. In-house finishing requires significant resources and expertise. Any inefficiencies or delays in this stage will affect delivery times and potentially customer satisfaction, making it harder to compete in the fast-paced world of trade printing.

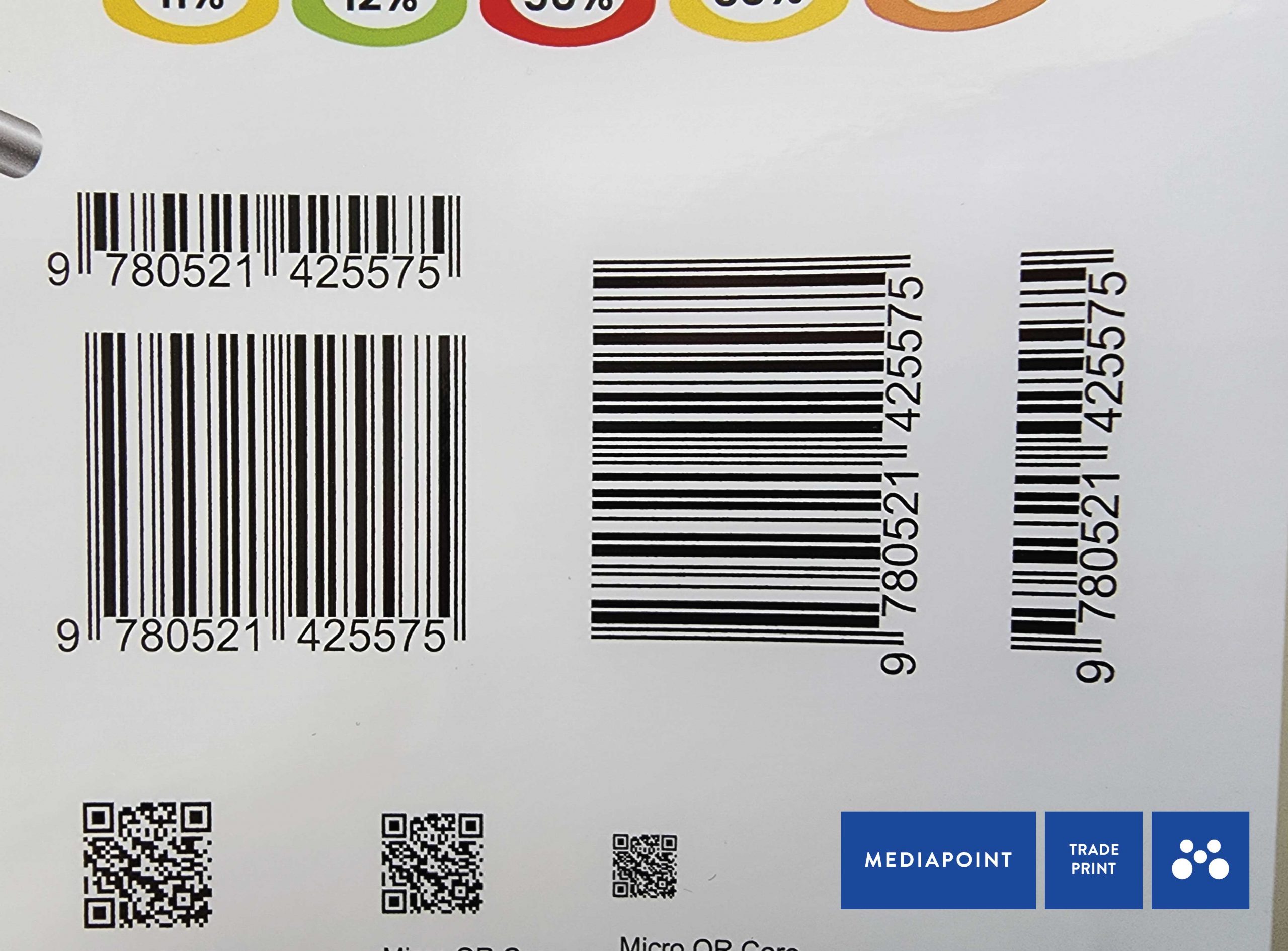

Quality Assurance and Dispatch

When dealing with wide format prints, the sheer size and scale of the materials necessitate additional quality control measures. Unlike smaller print jobs, large format printing requires rigorous quality checks before dispatch to ensure that every print is up to standard. Furthermore, shipping large prints often involves custom packaging solutions, which adds complexity to the dispatch process.

At Mediapoint, we’ve refined our quality assurance processes to ensure that every order meets client expectations. From custom packaging to careful handling during dispatch, we ensure that our large format prints arrive safely and in pristine condition.

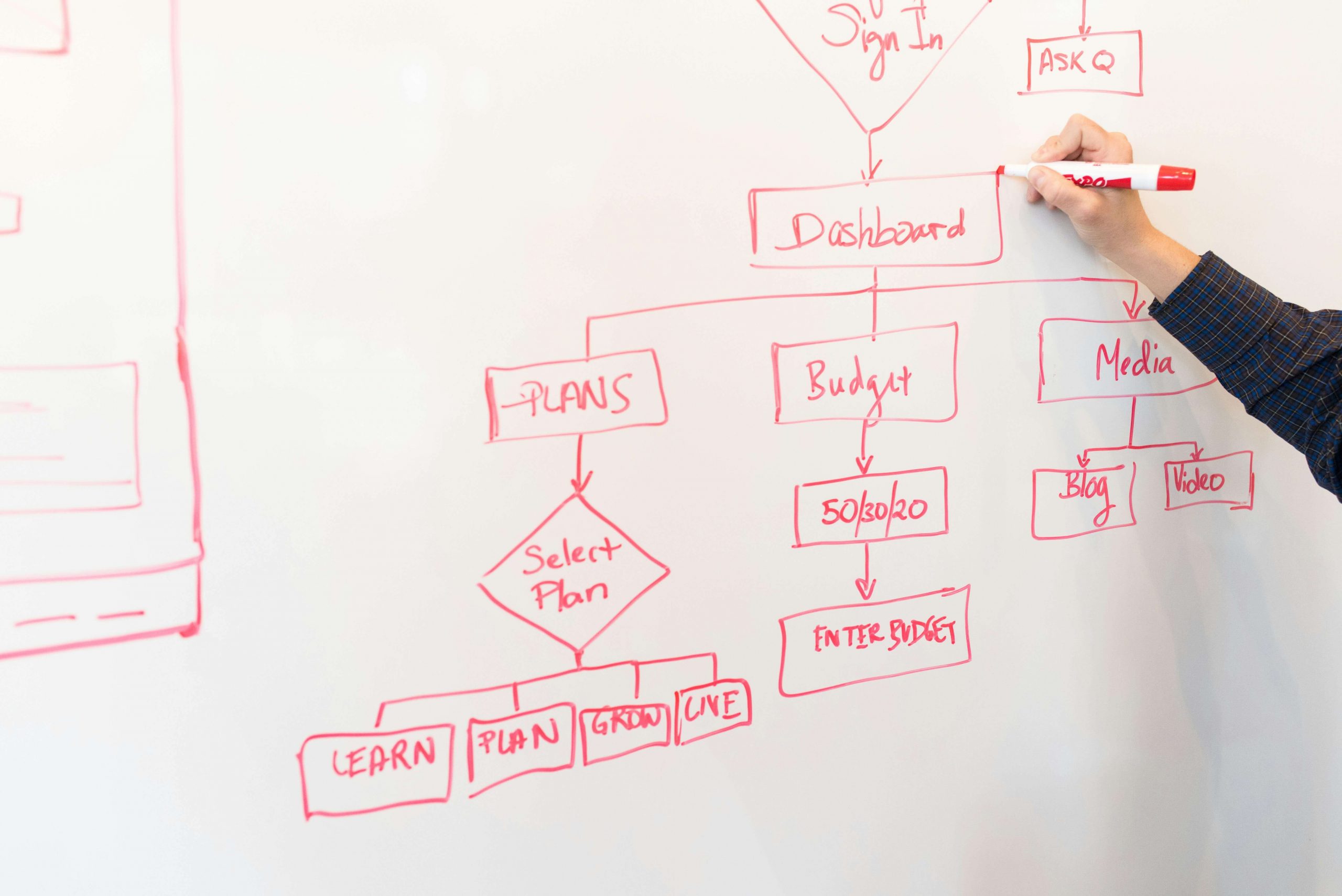

Additionally, we’ve integrated our operations with PrintIQ, an advanced system offering 24/7 live pricing and automated processing. This system allows our clients to get instant quotes and faster turnarounds, saving time and ensuring that projects are completed without delays.

The Benefits of Trade Printing

Now that we’ve broken down the various costs involved in large format printing—equipment, ink, space, finishing, and quality assurance—it’s clear that in-house production comes with a hefty price tag. For many businesses, these costs can be prohibitive, especially when considering the high volumes needed to make the investment worthwhile.

Trade printing, on the other hand, offers a cost-effective alternative. By partnering with Mediapoint, print resellers and brokers can take advantage of our investments in technology, space, and processes, without having to shoulder those expenses themselves. This enables you to offer competitive pricing and superior quality to your clients, while still maintaining healthy profit margins.