In this article we take a quick look at an often overlooked element of sticker and label printing – the cutting technique.

With their vast array of applications, it is crucial that labels are printed optimally to minimise waste and extend application life. Whilst it may seem like a trivial, simple feature of a label or sticker – it can in fact make a significant difference in the product you receive.

The importance of how stickers and labels are cut often gets missed by sub-par operators. Also, certain technologies (like rear-cutting laser) are too expensive of an investment for some trade printers.

At Mediapoint we precisely cut and crafted our stickers and labels using this cutting-edge (no pun intended) technology to provide our print resellers the best outcomes. Here’s how and why we have invested into getting sticker and label cutting right.

Sticker and Label Cutting Influences Perceived Quality

Precision cutting is the foundation for creating stickers and labels that are both visually appealing and functional. A well-cut label not only enhances the overall appearance of a product but also ensures its durability and longevity.

When cut properly a label will have crisp edges that provide a clean finish and reduce the likelihood of issues during peeling from the roll. With precision cutting, stickers and labels can be crafted into various shapes and sizes, allowing for greater customisation and creativity.

Cutting technique also influences cost-effectiveness of sticker and label printing. Good cutting minimises waste material and reduces the need for reprints. That means faster turnaround and less production costs – giving you more margin.

Why Laser Cutting on the Rear Side Is Best

Laser cutting on the rear side is the optimal choice for sticker and label printing. It offers numerous advantages over traditional cutting methods, yet aside from Mediapoint there are few trade printers offering this in Australia.

So what does it offer?

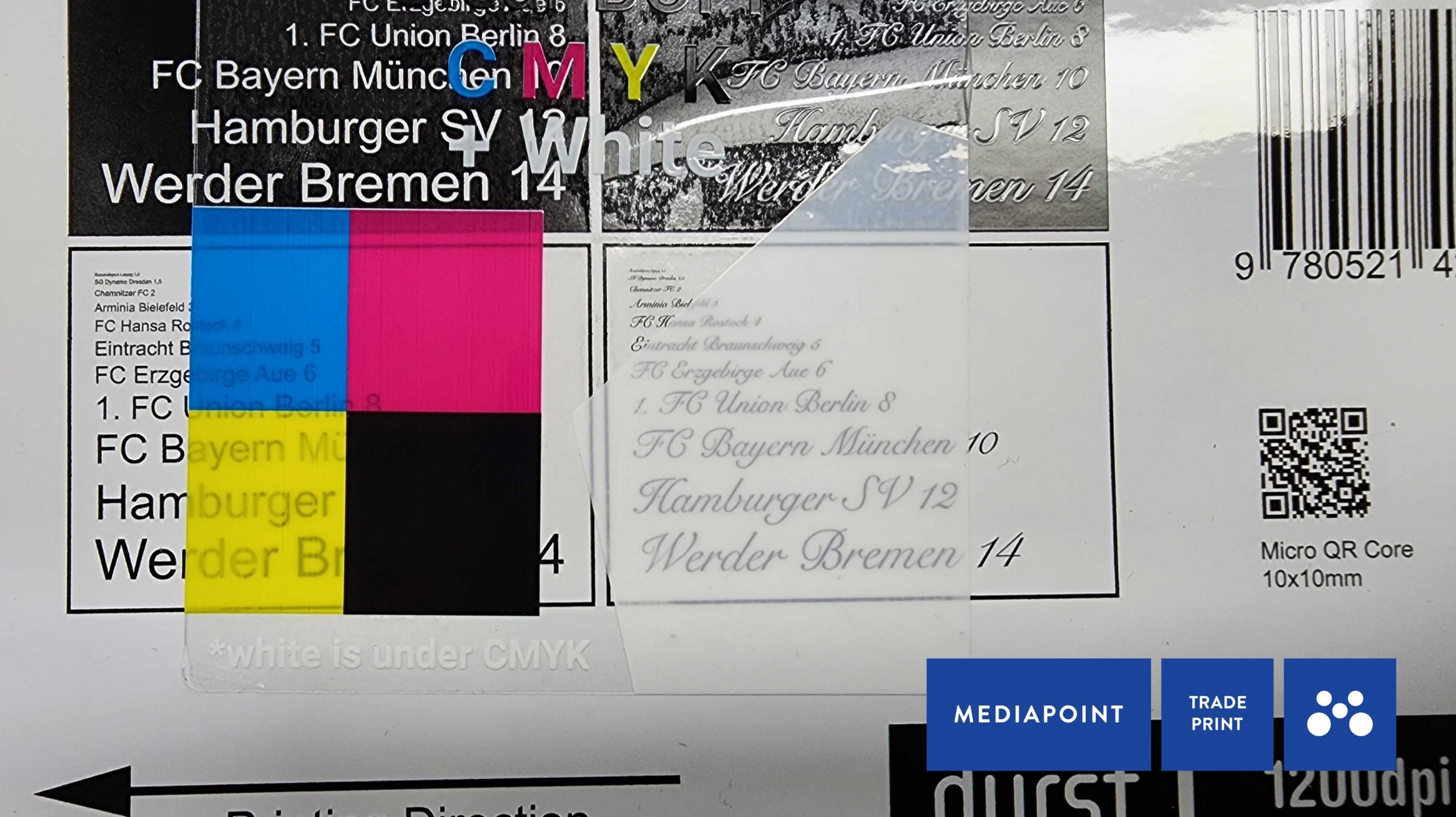

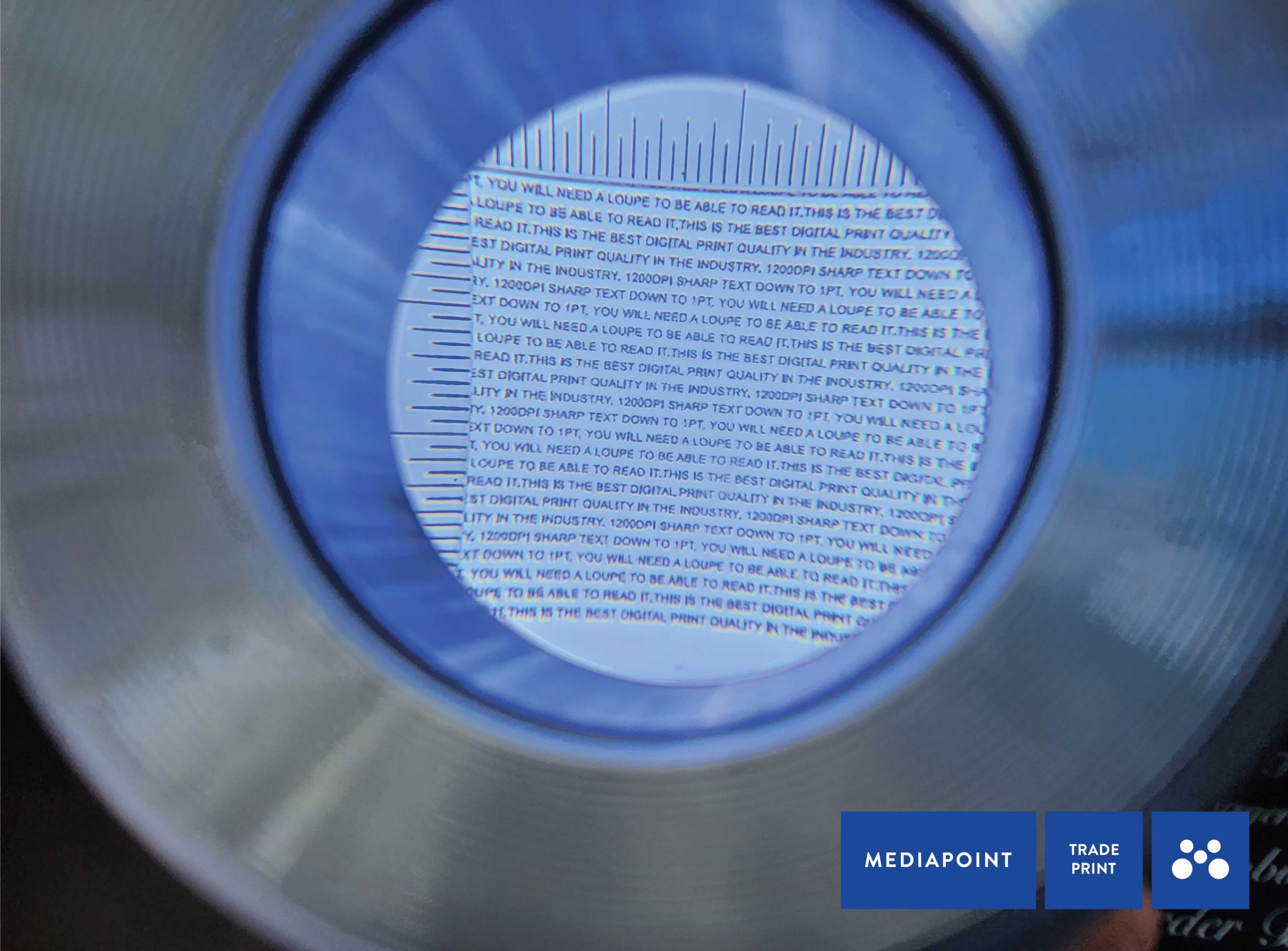

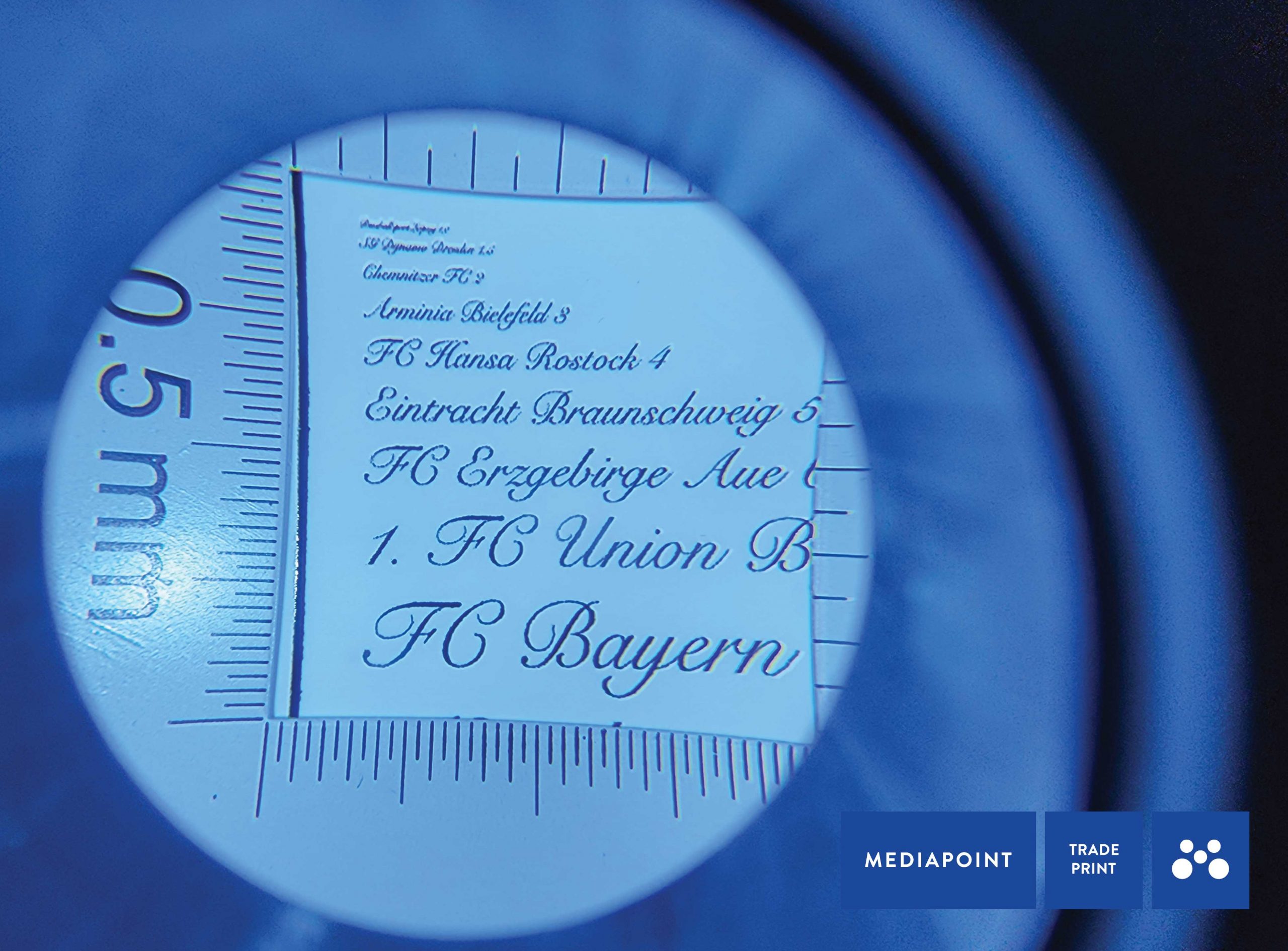

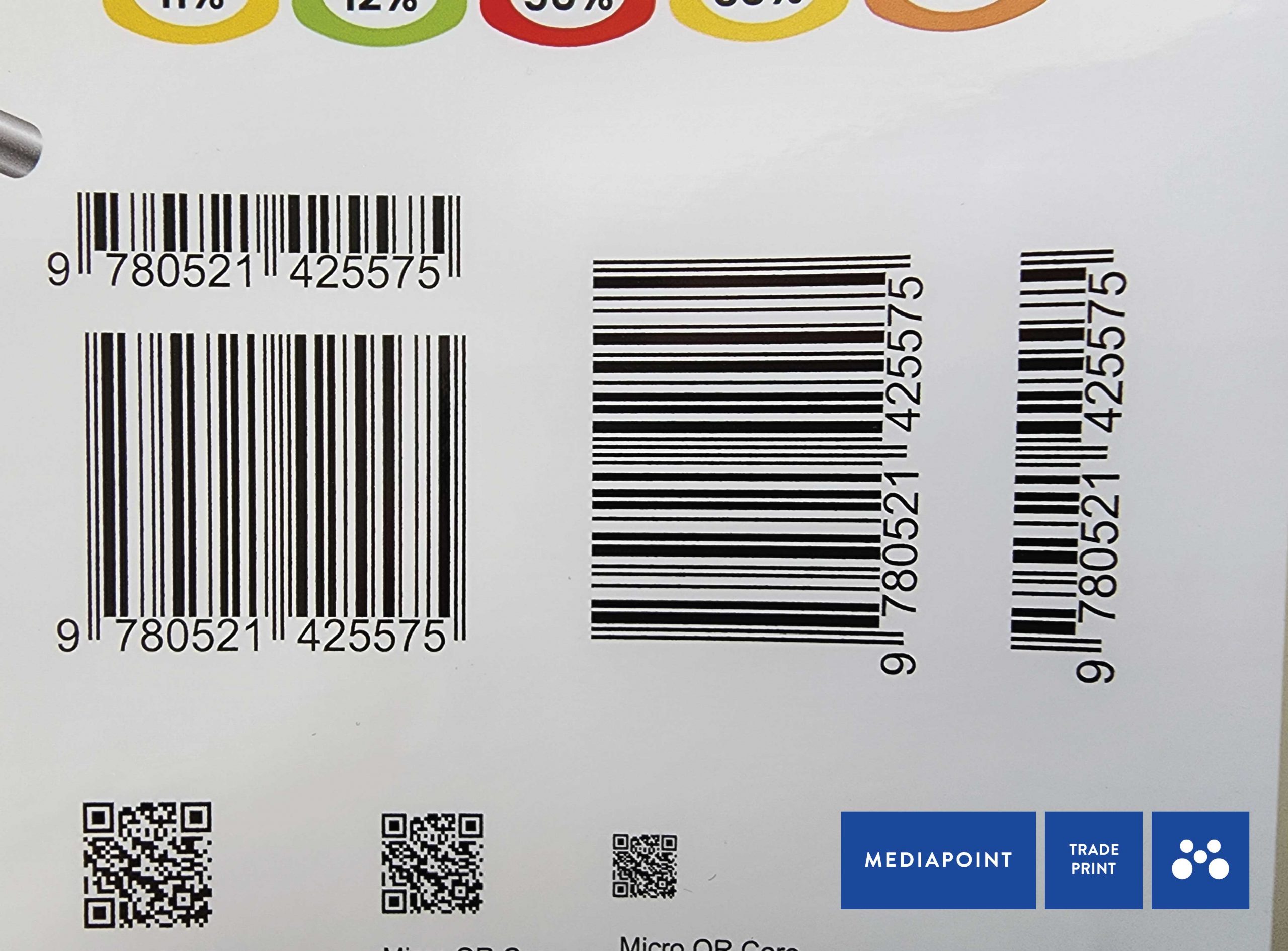

- Precision and Accuracy: Laser cutting provides unparalleled precision, allowing for intricate shapes and designs that might be impossible to achieve with other cutting methods.

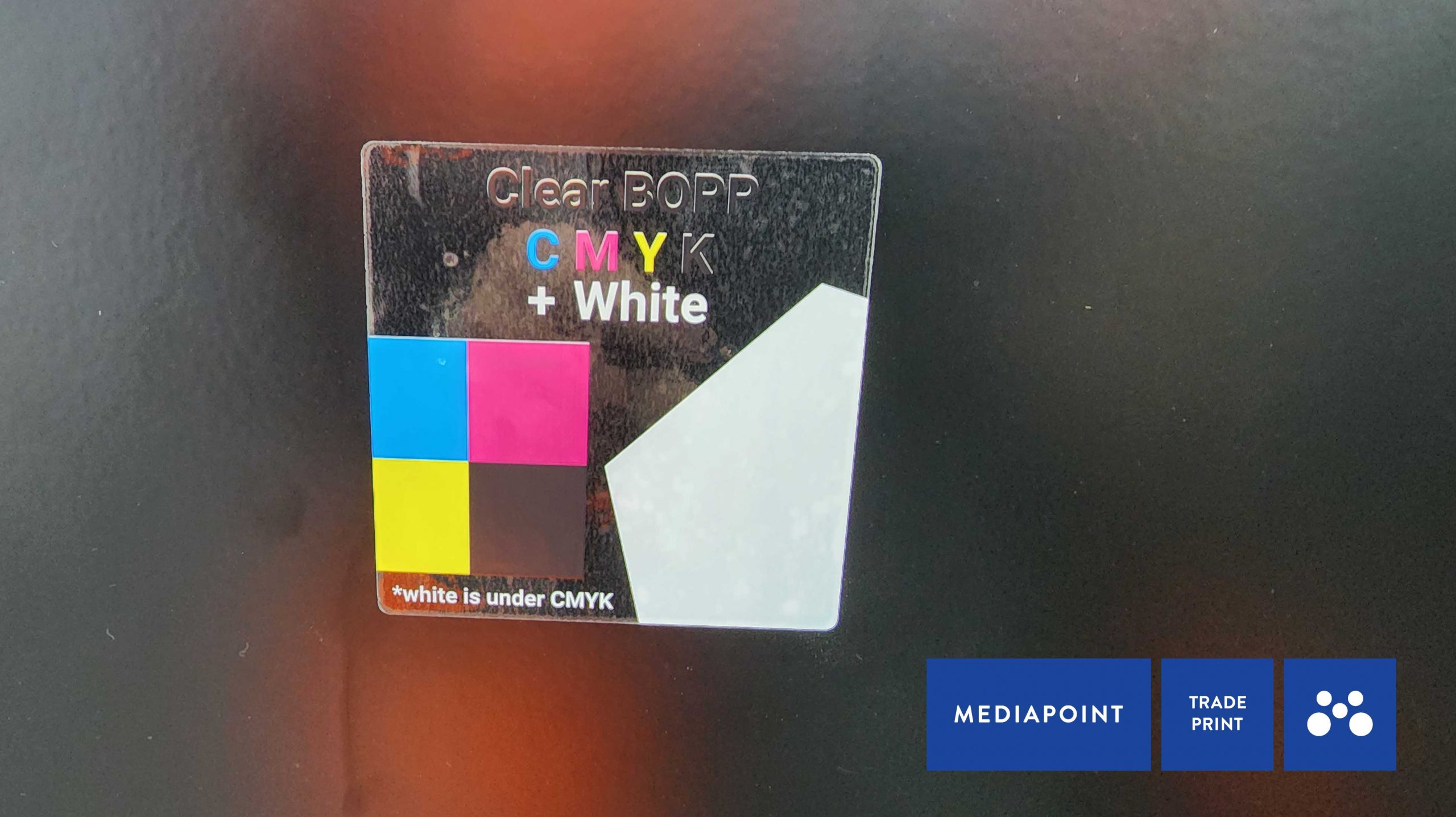

- Minimal Material Damage: By cutting from the rear side, the laser avoids direct contact with the sticker or label’s printed surface, significantly reducing the risk of damage or distortion to the artwork. A print job with front-cut will often have white edges around artwork do accomodate the burning effect of the laser. This wastes material and requires a compromise on artwork.

- Enhanced Efficiency: Laser cutting is a non-contact method, eliminating the need for physical cutting tools. This results in faster production times so you can get jobs faster.

- Flexibility: Laser cutting is highly adaptable, capable of working with a wide range of materials and thicknesses, making it suitable for a variety of sticker and label applications.

How We Conduct Label and Sticker Printing

At Mediapoint, we’re committed to delivering superior quality at the best cost for any print job. That dedication extends to sticker and label printing. Here’s a quick recap of why print resellers and brokers choose us as their trade printing partner:

- We utilise the latest technology to ensure quality printing. When it comes to stickers and labels we’re one of the only trade printers to offer rear-cut options that offer the highest level of precision.

- Our ordering system is online, self-service and fully-automated. This provides 24/7 live pricing and ordering. This means resellers and brokers can make the most margin whilst getting jobs completed faster.

- We have almost 2 decades experience in the Australia print industry meaning our processes are optimised to a tee – ensuring quality results and the fastest turnaround times.

- We are committed to maintaining the highest standards of quality. We implement rigorous quality control measures so you don’t have to worry about a thing. Just follow our ordering prompts, proof artwork online and leave it it us.

So if you’re looking to offer your customers quality stickers and labels, and need a trade print partner to take care of the volume – talk to us.