Welcome to Mediapoint’s Labels and Stickers Stock Guides. This page is dedicated to providing you with detailed specifications and insights for our range of label and sticker materials. By familiarising yourself with these guides you can ensure that your designs will meet expectations and application requirements.

White BOPP

Our White Gloss BOPP is an ultra white polypropylene top coated film designed for ultimate label application conformation on many difficult and contoured surfaces. Supplied with a clean crisp white finish for optimum screen and print tone resolution.

White BOPP Technical Data PDF: DOWNLOAD HERE

Details at a Glance:

- White Gloss Polypropylene

- Matt and Gloss Laminates available for this stock

- Waterproof

- Dishwasher, Fridge and Freezer safe

- Acylic Adhesive

- 54gsm Face

- Application Temperature above -5 degrees celsius

- Service Temperature range -40 degrees celsius to 120 degrees celsius

- Backing is 65gsm Glassine liner

Product Overview:

The Mediapoint Gloss White BOPP (Biaxially Oriented Polypropylene) is a premium label stock that combines exceptional durability with a high-gloss finish. It is designed to provide your products with a superior presentation that stands out on the shelves. The material is resistant to water, oil, and most household chemicals, making it ideal for applications that require a robust label, including food and beverage products, cosmetics, and bath and body products.

Features:

- High-Gloss Finish: Ensures vibrant print clarity and colour brilliance.

- Water Resistant: Suitable for refrigerated products and beverages.

- Oil and Chemical Resistant: Ideal for products exposed to harsh environments.

- UV Resistant: Maintains print quality and colour integrity under exposure to sunlight.

- Easy Application: The adhesive is designed for easy application and strong adherence to a variety of surfaces.

Specifications:

- Material: Gloss White Biaxially Oriented Polypropylene (BOPP)

- Adhesive: Permanent acrylic adhesive

- Maximum Roll Width: 1300 mm

- Maximum Roll Length: 1000 m

- Printing Technology Compatibility: Compatible with most major printing technologies including flexographic, digital, and thermal transfer.

Applications:

- Food and Beverage Labels: Ideal for bottled products, jar labels, and refrigerated goods.

- Cosmetic Labels: Perfect for beauty products that are frequently handled and stored in various environments.

- Chemical Product Labels: Resists degradation from industrial oils, solvents, and cleaners.

- Health and Wellness Products: Labels that stay intact on products often stored in wet environments like bathrooms.

Ordering Information: For more details on ordering Mediapoint White BOPP, including custom sizes and volume discounts, please contact our sales team at sales@mediapoint.com.au or visit our website at www.mediapoint.com.au.

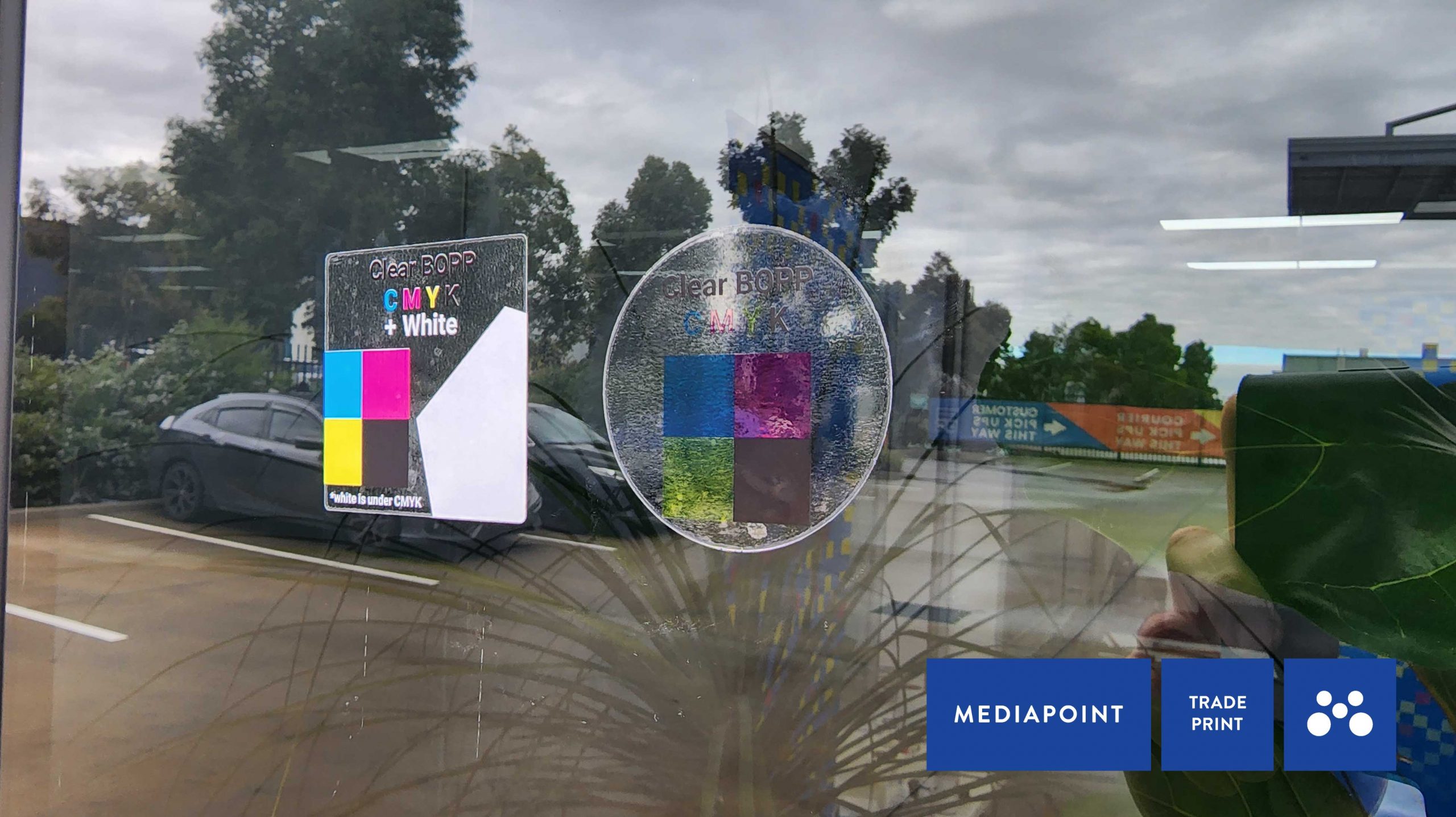

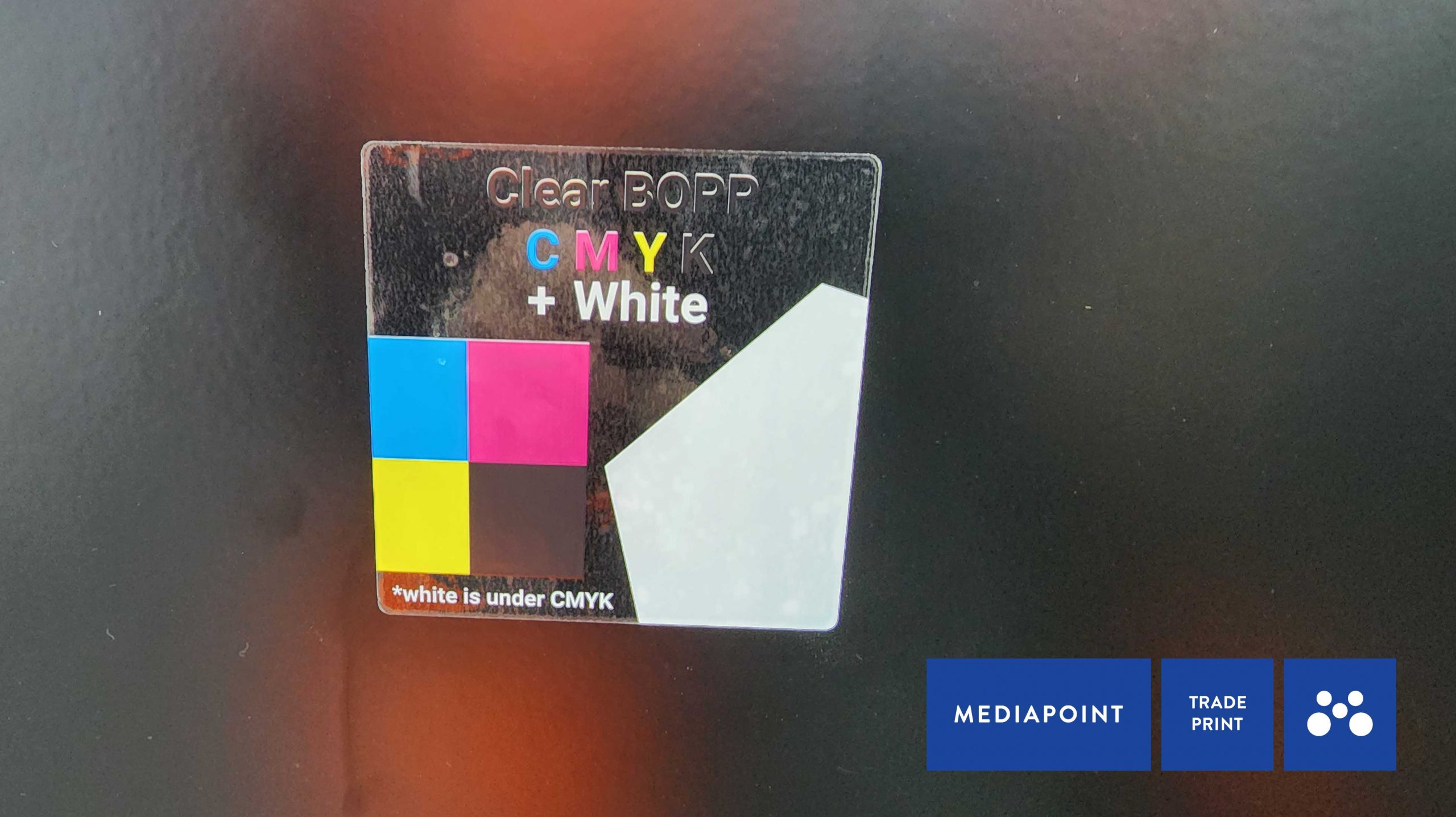

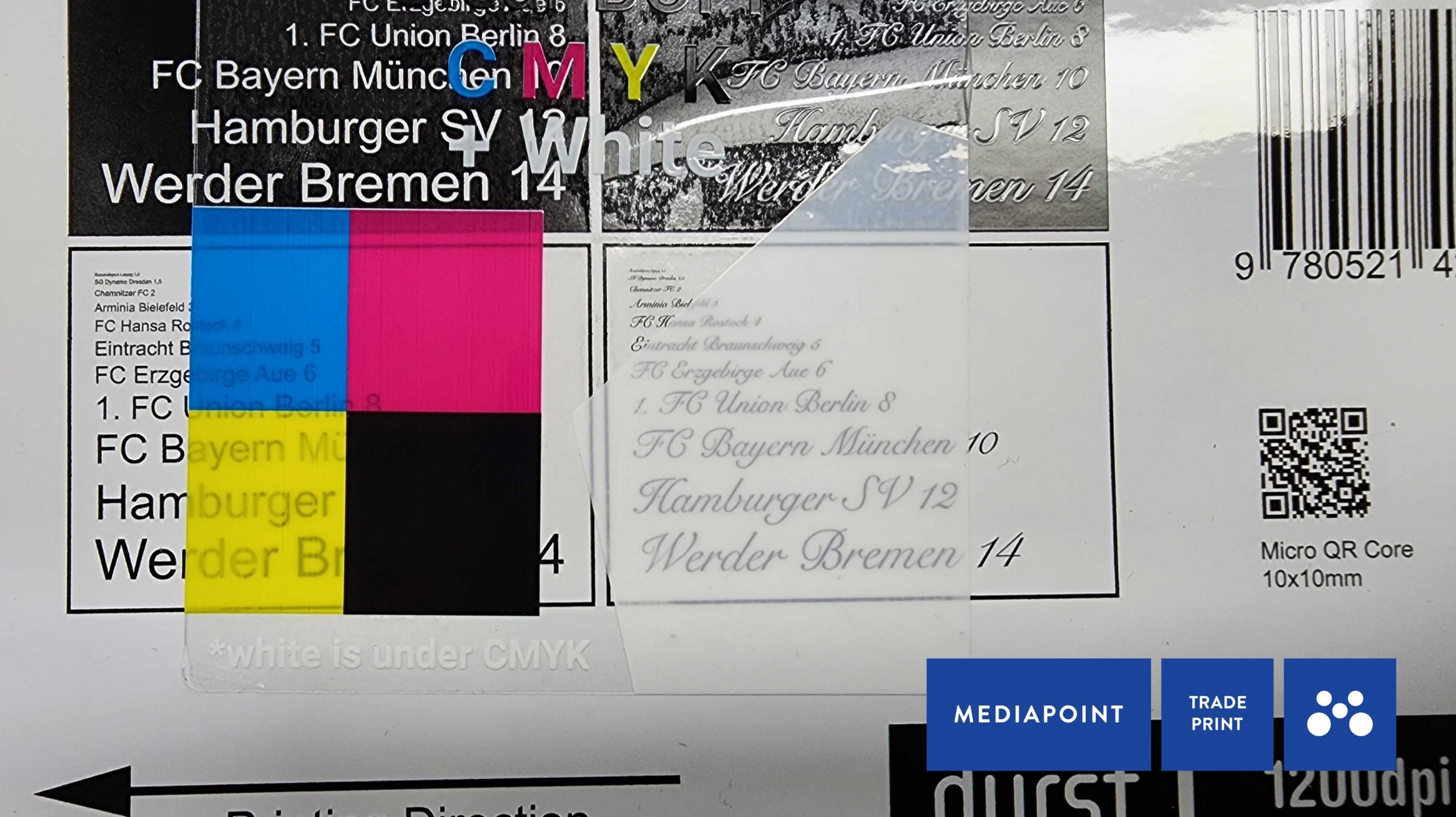

Clear BOPP

Our Clear Gloss is a clear polypropylene top-coated film designed for ultimate label application conformity on many difficult and contoured surfaces. It provides excellent clarity for optimum print results and label performance, ensuring a cloud-free, high-resolution finish.

Clear BOPP Technical Data PDF: DOWNLOAD HERE

Details at a Glance:

- Clear Gloss Polypropylene

- Laminate not available for this stock

- White Ink is available on this stock

- Waterproof

- Dishwasher, Fridge and Freezer safe

- Permanent Acylic Adhesive

- 45gsm Face

- Application Temperature above -5 degrees celsius

- Service Temperature range -40 degrees celsius to 120 degrees celsius

- Backing is 56gsm Glassine liner

Product Overview:

The Clear Gloss is a clear polypropylene top coated film designed for ultimate label application conformation on many difficult and contoured surfaces. Multiple features of this gloss make it a versatile and reliable choice for a variety of labelling applications, particularly where clarity and durability are paramount.

Features:

- Clear Polypropylene Top-Coated Film: Provides a high clarity film that ensures optimal print results and label performance, giving a cloud-free and high-resolution finish.

- Ultimate Label Conformity: Designed for ultimate application conformity on many difficult and contoured surfaces, making it suitable for complex packaging needs.

- Durability: Constructed with a durable face-stock that is ideal for prime labels, especially in the body care industry where labels may be subject to frequent handling.

- UV Exposure Resistance: Offers up to 6 months of UV exposure resistance depending on ink coverage, ensuring longevity under sunlight.

- General Purpose Permanent Adhesive (AP901): Features a water-based acrylic adhesive that provides high cohesion and excellent clarity. It performs very well on apolar substrates such as PE and PP, and is approved for direct skin contact applications like plasters.

- Temperature Resilience: The adhesive can handle a wide range of temperatures, with an application temperature minimum of -5°C and a service temperature ranging from -40°C to +120°C.

- Laminate Longevity: Comes with a 24-month shelf life when stored at optimal conditions (20°C/50% RH), ensuring long-term usability without degradation in quality.

Technical Data:

- Grammage (ISO 536): 45 g/m²

- Caliper (ISO 534): 50 microns

- UV Exposure: 6 months depending on ink coverage

- Adhesive: AP901 General Purpose Permanent

- Composition: Water-based acrylic

- Direct Sunlight Resistance: Excellent

- Cohesion: High

- Application Temperature: Minimum -5°C

- Service Temperature: -40°C to +120°C

- Tack (FTM9): 8N/Inch

- Ultimate Adhesion (FTM2): 7N/Inch

Laminate:

- Shelf Life: 24 months at 20°C/50% RH

- Typical Laminate Caliper: 124±6 µm

- Total Weight: 130±6

Backing:

- Type: WG White Glassine (1 side siliconised)

- Grammage: 65 gsm

- Caliper: 56 microns

- Transparency: >40%

Silver BOPP

Our Silver BOPP is a 50-micron top-coated silver polypropylene film with a brilliant gloss surface, ideal for crisp colour reproduction and optimum print results. It supports various print methods including letterpress UV, screen, flexographic, and offset printing.

Silver BOPP Technical Data PDF: DOWNLOAD HERE

Details at a Glance:

- Silver Polypropylene

- Matt and Gloss Available on this stock

- Waterproof

- Dishwasher, Fridge and Freezer safe

- White Ink is available on this stock

- Permanent Acrylic Adhesive

- 45gsm Face

- Application Temperature above -5 degrees Celsius

- Service Temperature range -40 degrees Celsius to 120 degrees Celsius

- Backing is 62gsm Glassine liner

Product Overview: The Silver Bopp is a top choice for high-quality, durable labels that require a metallic appearance with superior print clarity. The adhesive properties and durability of inks make this suitable for water, food & beverage, household, chemical, and point-of-sale labels.

Features:

- Metallised Silver Polypropylene Film: This top-coated silver polypropylene film has a brilliant gloss surface that enhances crisp colour reproduction and optimizes print results.

- Versatile Printing Compatibility: Suitable for various printing methods including letterpress UV, screen, flexographic, and offset printing, making it adaptable for different label production requirements.

- Durability and Label Performance: Designed for use in applications where a demanding label substrate is required, including labels for water, food & beverage, household products, chemicals, and point of sale.

- High Cohesion Adhesive: Equipped with AP901 general purpose permanent adhesive, known for its high cohesion, good clarity, and excellent performance on non-comparable substrates (PE, PP). This adhesive is also approved for direct contact with skin, suitable for products like plasters.

- Excellent Sunlight Resistance: The adhesive provides excellent resistance to direct sunlight, ensuring that the labels maintain their integrity and appearance over time.

- Broad Temperature Range: The adhesive supports a broad temperature range with a minimum application temperature of -5°C and a service temperature range from -40°C to +120°C.

- Laminate Features: Includes a laminate shelf life of 24 months when stored at 20°C and 50% relative humidity. The typical laminate caliper is 130±6 microns with a total weight of 128±6 grams per square meter.

Technical Data:

- Grammage (ISO 536): 45 g/m²

- Caliper (ISO 534): 50 microns

- Adhesive: AP901 General Purpose Permanent

- Composition: Water-based acrylic

- Direct Sunlight Resistance: Excellent

- Cohesion: High

- Application Temperature: Minimum -5°C

- Service Temperature: -40°C to +120°C

- Tack (FTM9): 8N/Inch

- Ultimate Adhesion (FTM2): 7N/Inch

Laminate:

- Shelf Life: 24 months at 20°C/50% RH

- Typical Laminate Caliper: 130±6 µm

- Total Weight: 128±6

Backing:

- Type: WG White Glassine (1 side siliconised)

- Grammage: 62 gsm

- Caliper: 55 microns

Matte Paper

Our two-sided label matte paper is a high quality machine-coated paper with a crisp matt white finish. It offers superior thermal transfer printing capabilities and colour reproduction.

Matte Paper Technical Data: DOWNLOAD HERE

Details at a Glance:

- Matte Paper

- Ink has a gloss finish

- No laminates available on this stock

- Stock is thermal printable (the ink is not)

- Permanent Acrylic Adhesive

- 82gsm Face

- Application Temperature above 5 degrees Celsius

- Service Temperature range -20 degrees Celsius to 70 degrees Celsius

- Backing is 62gsm Glassine liner

Product Overview:

These Matte finish two-sided labels are made of high quality, wood-free, machine coated paper with excellent whiteness. The matt surface means greater thermal print transfer and superior colour reproduction – so your labels will pop with colour as intended.

Features:

- Metallised Silver Polypropylene Film: This top-coated silver polypropylene film has a brilliant gloss surface that enhances crisp colour reproduction and optimizes print results.

- Versatile Printing Compatibility: Suitable for various printing methods including letterpress UV, screen, flexographic, and offset printing, making it adaptable for different label production requirements.

- Durability and Label Performance: Designed for use in applications where a demanding label substrate is required, including labels for water, food & beverage, household products, chemicals, and point of sale.

- High Cohesion Adhesive: Equipped with AP901 general purpose permanent adhesive, known for its high cohesion, good clarity, and excellent performance on non-comparable substrates (PE, PP). This adhesive is also approved for direct contact with skin, suitable for products like plasters.

- Excellent Sunlight Resistance: The adhesive provides excellent resistance to direct sunlight, ensuring that the labels maintain their integrity and appearance over time.

- Broad Temperature Range: The adhesive supports a broad temperature range with a minimum application temperature of -5°C and a service temperature range from -40°C to +120°C.

- Laminate Features: Includes a laminate shelf life of 24 months when stored at 20°C and 50% relative humidity. The typical laminate caliper is 130±6 microns with a total weight of 128±6 grams per square meter.

Technical Data:

- Grammage (ISO 536): 82 g/m²

- Caliper (ISO 534): 72 microns

- Adhesive: S-Type – Permanent Acrylic

- Peel Adhesion (N/25mm, FTM 1): 12.7

- Initial Tack (N/25mm, FTM 9): 7.8

- Cohesion (h, FTM 8): ≥ 3 hours

- Minimum Application Temperature: 5°C

- Service Temperature: -20 to 70°C

Laminate:

- Shelf Life: 24 months at 23°C/50% RH

- Typical Laminate Caliper: 142 microns (162gsm)

Backing:

- Type: White Glassine

- Grammage: 62 gsm

- Caliper: 53 microns

- Opacity: 60%

Gloss Paper

This gloss paper is a lustrous wet-strength paper cellulose substrate with a high cast gloss surface, offering exceptional print and colour results.

Gloss Paper Technical Data PDF: DOWNLOAD HERE

Details at a Glance:

- Gloss Paper

- No laminates available on this stock

- Permanent Acrylic Adhesive

- 80gsm Face

- Application Temperature above -5 degrees Celsius

- Service Temperature range -40 degrees Celsius to 1200 degrees Celsius

- Backing is 65gsm Glassine liner

Product Overview:

This paper is crafted to enhance the visual quality of labels with its striking gloss finish, ensuring standout labels on any shelf. That makes this product versatile and suitable for a wide array of applications including wine and beverage labelling, as well as health and cosmetic labels. Its robust properties make it ideal for environments where moisture resistance and aesthetic appeal are crucial.

Features:

- High Cast Gloss Surface: Delivers exceptional print and color results with a premium gloss finish that ensures labels are visually striking and vibrant.

- Wet-Strength Paper: Crafted from a robust wet-strength paper cellulose substrate, Verdure Lustre is highly resistant to moisture, making it ideal for labels that may be exposed to wet or humid conditions.

- Versatile Applications: Perfect for a wide range of labeling needs, including wine and beverage labels, health products, and cosmetics, providing flexibility for various industry requirements.

- Superior Adhesion Qualities: Features a pure acrylic adhesive (AP903) that offers good adhesion across a broad temperature range, which is crucial for maintaining label integrity in varying environmental conditions.

- Excellent Clarity for Wet and Cold Surfaces: The adhesive is designed to provide clear and durable label adhesion, particularly effective for applications like wine labels that are stored in cold and moist environments.

- Good Direct Sunlight Resistance: Ensures that the labels maintain their visual appeal and do not degrade when exposed to sunlight, preserving the product’s branding.

- Low Cohesion: While providing strong initial tack, the adhesive allows for easier handling and application, making it user-friendly for labeling operations.

- Durable and Reliable: The laminate and backing materials are designed to support the longevity and durability of labels, with a laminate shelf life of 24 months when stored properly.

Technical Data:

- Grammage (ISO 536): 80 g/m²

- Caliper (ISO 534): 86 microns

- Adhesive: AP903

- Type: Pure acrylic adhesive formulation

- Characteristics: Offers good adhesion across a broad temperature range, excellent clarity for wet and cold surfaces which is particularly advantageous for wine labels.

- Direct Sunlight Resistance: Good

- Cohesion: Low

- Application Temperature: -5ºC (minimum)

- Service Temperature: -40ºC to +120ºC

- Tack (FTM9): 8 N/inch²

- Ultimate Adhesion (FTM2): 9 N/inch

Laminate:

- Shelf Life: 24 months when stored at 20ºC/50% RH

- Typical Laminate Caliper: 164±6 microns

- Total Weight: 167±6 grams per square meter

Backing:

- Type: WG White Glassine – 1 side siliconised supercalendered white glassine

- Grammage: 65 gsm

- Caliper: 56 microns

- Transparency: > 45%